On my model 900 it is an older version that still has the Delrin bushing supporting the spindle. I never noticed a problem with the spindle until I attached a faceplate to my mill. Now, you will not find mounting a face plate to be an option in the official manual, but like the boy's at legacy say, "The only limitation is your Imagination".

When I mounted the face plate, I noticed that my cut was uneven on the face. I was using a side cutting bit and my TK Reciprocator. The depth of cut kept moving around on me. That is when I noticed the spindle was moving in and out of the headstock.

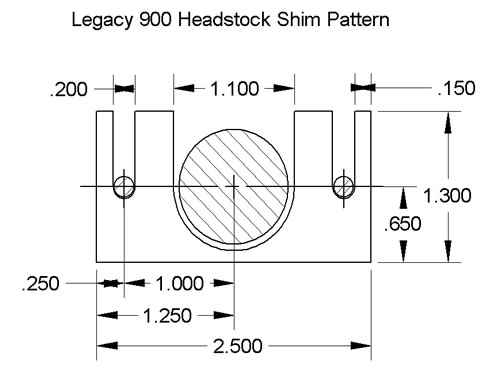

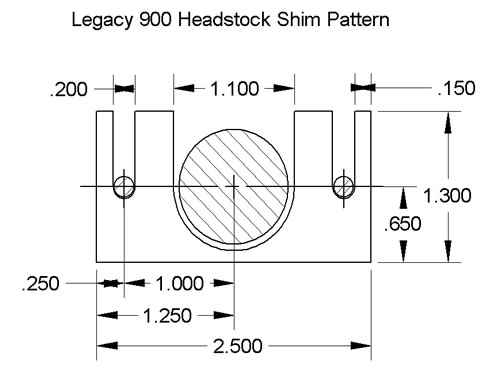

To fix the problem I first measured the travel of the spindle. In mine it was .023". I have to admit I can be pretty lazy. So, rather than tearing apart the whole headstock to install a shim, I created this pattern.

To create the shim, I searched all over town for shim stock. It's not as easy to find as it use to be. So, I ended up at a hobby shop, and found a material called "Sheet Styrene". It wonderful stuff, and is found in the railroad section. It comes in various sizes. I used a sheet of .020" material and cut the above shape with a knife and scissors.

After loosening the two screws that holds the Delrin block in the front, I inserted the shim between the delrin and the metal wall. That way, the clip on the spindle still rides against the delrin. Only now my spindle has only .003" of movement.

One thing I have noticed on several machines is the screws that hold the Delrin bearings are only 1/2" long and use a standard nut that is only hanging on by a few threads. I changed my screws to 3/4" long and added nylon lock nuts.

Disclaimer: I am not associated with Legacy Woodworking or Phantom Engineering.

If you have any question or comments, please feel free to email me. Tim

Web Page updated 2-15-11 All right reserved.